Winter's icy grip can be formidable, and for F 150 owners equipped with a Boss plow attachment, a reliable electrical system is paramount. However, encountering F 150 Boss Plow Attachment Wiring Problems can turn a powerful snow-clearing machine into a frustratingly immobile hunk of metal. These wiring issues, often subtle at first, can escalate quickly, leaving you stranded when you need your plow the most.

Understanding F 150 Boss Plow Attachment Wiring Problems

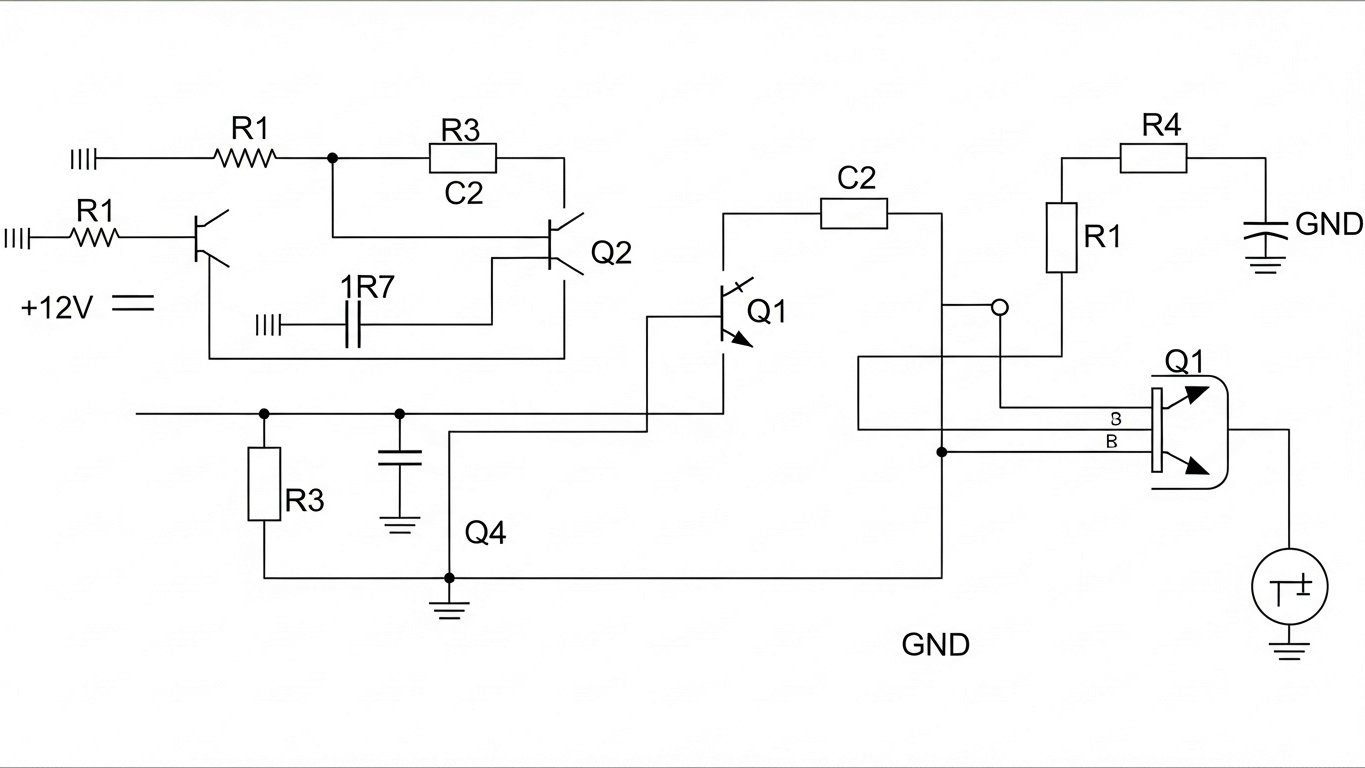

F 150 Boss Plow Attachment Wiring Problems refer to any malfunction or issue within the electrical connections that power and control your Boss snow plow. These systems are designed to translate your truck's power into the hydraulic movements necessary for lifting, lowering, angling, and sometimes even oscillating the plow blade. When these wiring systems falter, the plow's functions become erratic or cease altogether.

The complexity of these systems means there are several potential points of failure. Common areas where F 150 Boss Plow Attachment Wiring Problems can manifest include:

- The main power harness connecting the truck battery to the plow's control unit.

- The control unit itself, which acts as the brain for the plow's operations.

- Wiring leading to the hydraulic pump and valve solenoids.

- The in-cab controller or joystick, responsible for user input.

- Ground connections, which are crucial for completing electrical circuits.

Diagnosing and resolving F 150 Boss Plow Attachment Wiring Problems is essential because a properly functioning wiring system is the backbone of your snow removal operation, ensuring safety, efficiency, and the longevity of your equipment. Ignoring these issues can lead to more severe damage, costly repairs, and potentially unsafe operating conditions. Consider this table outlining common symptoms and their potential wiring culprits:

| Symptom | Potential Wiring Problem |

|---|---|

| Plow doesn't move at all | Blown fuse, loose main power connection, faulty control unit |

| Plow only lifts but won't lower | Issue with lowering solenoid wiring or control signal |

| Plow angles erratically | Loose or damaged wiring to angle solenoids, faulty controller |

| Lights on plow don't work | Separate lighting circuit issue, blown fuse for lights |

When faced with these challenges, having a reliable resource to guide you through troubleshooting is invaluable. The information and solutions provided in the sections that follow are designed to help you navigate these complex electrical pathways.

For comprehensive and detailed guidance on tackling F 150 Boss Plow Attachment Wiring Problems, refer to the specific diagnostic procedures and repair tips available in the subsequent sections.