The Unseen Guardian of Engine Timing The Ford 2 Wire Crank Sensor Wiring Diagram Explained

The crankshaft position sensor, often referred to simply as the crank sensor, is a small but incredibly important electronic component. Its primary job is to monitor the rotational speed and position of the engine's crankshaft. This information is then relayed to the vehicle's Powertrain Control Module (PCM), which uses it to precisely time critical engine functions. Without this constant feedback, the PCM would be unable to tell the fuel injectors when to spray or the ignition coils when to spark, rendering the engine inoperable. The Ford 2 Wire Crank Sensor Wiring Diagram illustrates the electrical pathway between this sensor and the PCM, highlighting the two essential wires that carry its vital data. These two wires typically carry different types of signals, though the specifics can vary slightly between different Ford models and years. One wire usually provides the sensor's power supply, while the other carries the signal back to the PCM. The sensor itself operates on a principle that converts the physical rotation of the crankshaft into an electrical signal. This often involves a small magnet and a coil of wire, or sometimes a Hall effect sensor. The PCM then interprets the pattern of these electrical pulses to determine the crankshaft's position and speed. The accuracy of this signal is paramount for optimal engine performance, fuel efficiency, and emissions control.When troubleshooting a no-start condition, rough idling, or poor acceleration, the crank sensor and its wiring are often primary suspects. A damaged wire, a faulty connection, or an obstructed sensor can all lead to incorrect readings or a complete loss of signal. To properly diagnose these issues, having a reliable Ford 2 Wire Crank Sensor Wiring Diagram is indispensable. It allows technicians to:

- Identify the correct wire colors for signal and ground.

- Test for voltage at the sensor connector.

- Check for continuity within the wiring harness.

- Verify the sensor's output signal.

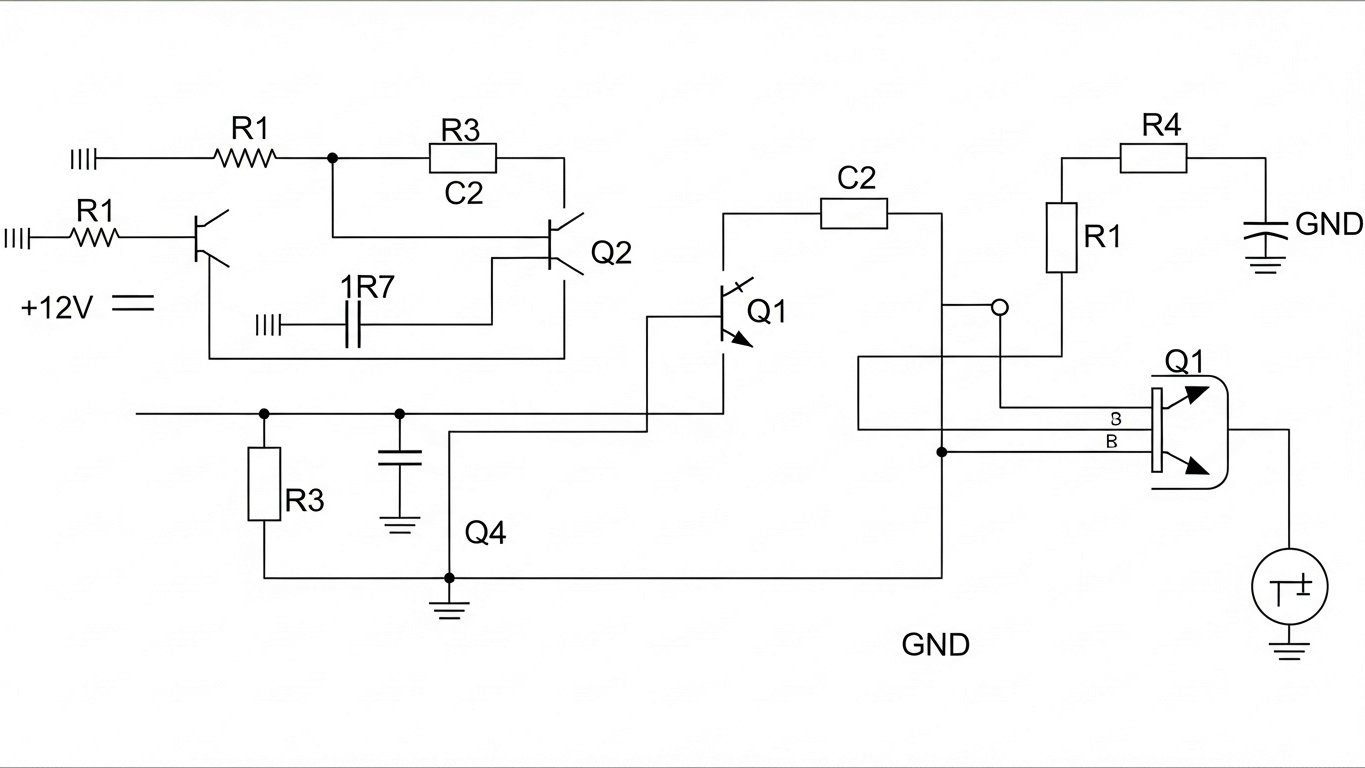

Here's a simplified representation of what a typical Ford 2 Wire Crank Sensor Wiring Diagram might show:

| Wire Function | Typical Color (May Vary) |

|---|---|

| Signal Wire | Often Red or Yellow |

| Ground Wire | Often Black or Brown |

This diagram serves as your roadmap for understanding the electrical integrity of your Ford's crankshaft position system. It's the key to tracing the signal from its source at the sensor all the way to its destination within the PCM.

For a comprehensive understanding and to avoid costly mistakes, it is highly recommended to consult the specific Ford 2 Wire Crank Sensor Wiring Diagram that matches your vehicle's year, make, and model.